Manage Operations Efficiently with Inventory Management Solutions

The way a business handles its inventory can greatly affect its overall success. Thus, understanding how to efficiently manage inventory is crucial for both small and large-scale businesses. Let’s explore the essential aspects of inventory management and how advanced inventory management software can revolutionize your business.

Understanding the Importance of Efficient Inventory Management

Inventory management is a crucial part of running any business that manufactures, buys, or sells products. At its core, inventory management involves controlling and overseeing the flow of goods into and out of a business to ensure optimal stock levels are maintained. Without a proper inventory management system and processes in place, businesses can face a host of problems, including missed sales opportunities, poor cash flow, poor vendor relations, and increased costs.

For manufacturers, inventory management is necessary to ensure adequate raw materials and components are in stock for production to run smoothly. Retailers and e-commerce businesses must accurately track inventory to prevent stockouts and lost sales. Distributors need visibility into current inventory across multiple warehouse locations to meet customer orders and optimize deliveries.

Due to its direct impact on sales, profits, and operational efficiency, inventory management should be a high priority for growing businesses of all sizes.

The Role of Inventory Management in Your Business

Fundamentally, inventory management involves continuously tracking stock levels of the various materials and products necessary for company operations. This includes monitoring the raw material components used in the manufacturing process, work-in-progress goods at different production stages, and making sure finished products ready for sale to customers. Robust inventory management leverages perpetual, real-time inventory monitoring to maintain precise counts as items enter and exit facilities. This up-to-date visibility facilitates control over stock quantities, allowing businesses to improve accuracy and avoid expensive stockouts from depleted inventory. In addition to current inventory status, advanced systems provide valuable analytics on usage velocities, turnover rates, item groupings, and demand patterns.

By distinguishing between fast-moving, moderately-moving and slow-turning inventory, businesses can optimize future stock planning and balancing. Overall, comprehensive inventory management delivers the foundational data and insights growing businesses need to efficiently coordinate manufacturing schedules and sales fulfillment while minimizing waste. By keeping optimal levels of key inputs and outputs, companies can meet production and customer requirements while managing inventory expenses.

Cost Implications of Poor Inventory Management

When inventory management practices are insufficient or lacking altogether, it leads to a wide range of detrimental effects, including:

- Lost sales and customers due to stockouts and backorders.

- Increased costs from expedited shipping of out-of-stock items.

- Poor cash flow from excessive inventory locking up working capital.

- Decline in product quality from spoilage or expiration of old stock.

Carrying costs of excessive inventory also accumulate in the form of extras such as taxes, insurance, warehousing, and logistics. Storage space itself becomes a major cost for companies holding unneeded retail inventory.

Obsolescence poses another risk for businesses keeping track with inadequate inventory controls and oversight. Materials, components, or finished products may become outdated or expire before they can be used, resulting in total loss.

For manufacturers, lacking real-time monitoring of work-in-progress inventory can lead to costly production inefficiencies. Advanced inventory management software can provide data to optimize workflows and processes.

How Efficient Inventory Management Contributes to Business Success

Effective inventory management provides businesses with numerous advantages that can transform inventory from a cost center into a driver of growth and profitability. With consistent product availability and faster order fulfillment, businesses can increase sales. Lean inventory levels and improved inventory turnover lead to better cash flow and reduced carrying costs. By gaining visibility into true demand through analytics, businesses can improve buying power, coordinate production and logistics, and optimize reordering points to meet customer demand while minimizing excess stock.

For retailers and e-commerce companies, inventory availability and quick delivery build brand loyalty, directly impact the customer experience, and make customers more likely to purchase again. With end-to-end alignment across the supply chain, effective inventory management practices empowers business leaders and enables growing businesses to experience higher growth, lower costs, and improved efficiency.

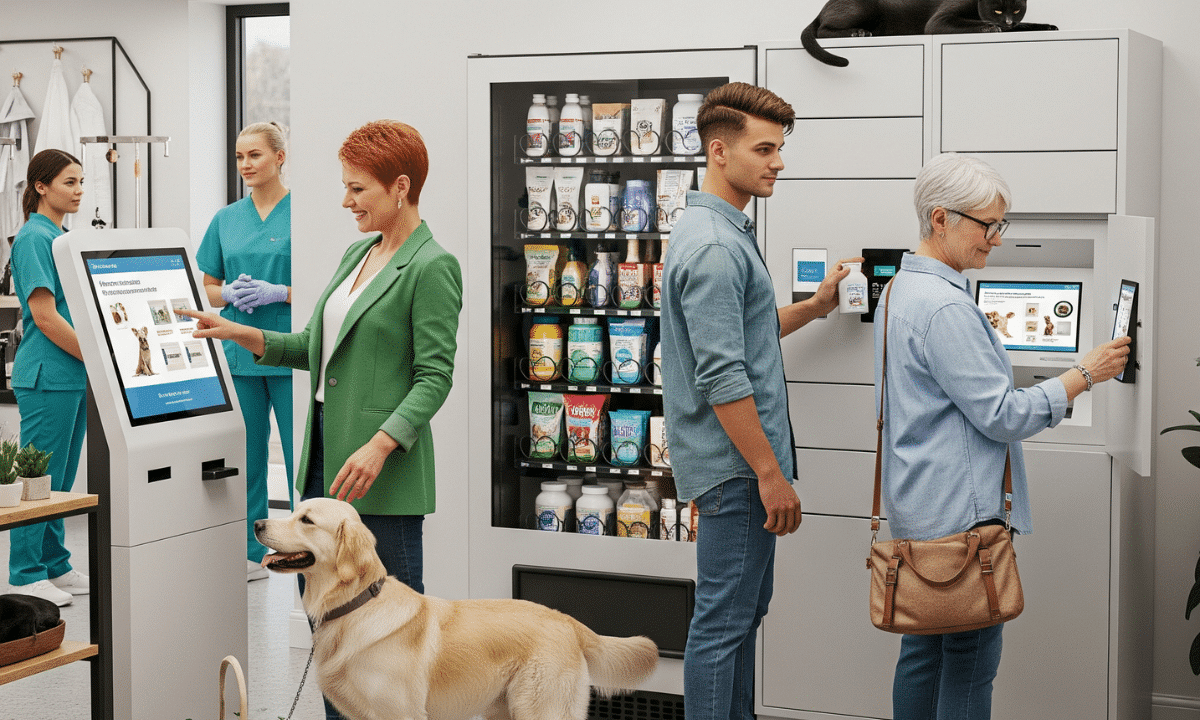

Exploring Smart Solutions for Inventory Management

Inventory management is a critical process for small businesses and large businesses. Having real-time visibility into inventory levels allows you to minimize waste, reduce costs, and ensure you have the right products available to meet customer demand. Advanced inventory management software provides intelligent solutions to automate and optimize complex inventory tracking tasks.

With smart inventory management solutions, businesses can track stock levels across multiple locations, generate accurate forecasts, and trigger automated replenishment orders. This saves considerable time and labor when compared to manual inventory tracking processes. Integrations with e-commerce platforms, pos systems, payment systems, and accounting software also provide a comprehensive view of the entire supply chain.

The Benefits of Implementing Smart Inventory Management Solutions

Intelligent inventory management platforms utilize automation, analytics, and machine learning to optimize inventory planning and provide business leaders with control beyond what manual approaches or basic software can deliver. By continuously and automatically tracking stock levels in real-time, they eliminate the need for repetitive manual counts and reduce the chance of human error when submitting purchase orders. The improved visibility into current inventory and predictive demand trends allows businesses to trim safety stock buffers that tie up working capital. Even as excess reserves are reduced, service levels can simultaneously improve through data-driven optimization of reorder points.

Additionally, algorithmic monitoring of expiration dates and seasonal demand shifts facilitate better stock rotation to minimize write-offs from waste. Machine learning mechanisms process historical data, detect evolving demand patterns, and account for external factors to provide more accurate forecasts. Across procurement, warehouse operations, and sales fulfillment, intelligent inventory management systems enable leaner, more responsive supply chain execution while mitigating out-of-stocks that impact revenues. This transforms inventory from a cost center into a profit driver.

Cost Considerations and Analysis

Transitioning to a new inventory management system requires careful evaluation of costs versus benefits. Upfront software, hardware, and integration expenses can be substantial, with many solutions requiring significant investments in barcode scanners, sensors, RFID tags, and devices. Ongoing fees for data connectivity, cloud hosting, and vendor support also accumulate over time. Implementation touches many stakeholders, necessitating changes to processes, workflows, and reporting. Comprehensive employee training and change management drives adoption but requires time and resources.

However, the right technology, properly executed, provides ROI through enhanced inventory visibility, accountability, and insights to optimize stock levels. Companies can better balance service levels against carrying costs. Inventory accuracy improves while write-offs, waste, theft and dead stock diminish. Operations become more responsive and efficient via automation. Together, these benefits reduce overall inventory expenses while improving returns. Cash flow, asset tracking and returns, and profitability all stand to benefit.

Determining the total cost of ownership and identifying major benefit opportunities allow businesses to develop a business plan with timelines for seeing expected gains. Phased deployment transitions inventory categories incrementally to control costs. Companies should work with solution vendors that can provide tools scaled for flexibility. As market competition and innovations accelerate, increasingly affordable systems and cloud cost structures lower adoption barriers – making inventory management success more accessible.

Practical Steps to Improve Inventory Management with Smart Solutions

Inventory management systems are a crucial aspect of running any product-based business. However, it can be easy to let things slip through the cracks without proper systems and processes in place. Implementing a few practical steps using technology and automation can significantly improve inventory management and avoid costly mistakes.

The first step is to invest in cloud-based inventory management software. This type of inventory solution gives you real-time visibility and control over stock levels across multiple locations and sales channels. The software centralizes all inventory data and syncs with your sales platforms, so you always know what you have on hand.

Integrating barcode scanning and mobile devices allows for streamlined stock tracking. Staff can quickly scan products in and out of inventory as they are received, picked, packed, and shipped. This eliminates manual data entry errors.

Adopting a Cloud-Based Inventory Management Solution

Transitioning to a cloud-based system makes the most sense for modern businesses. This enables access to inventory data from anywhere via web and mobile apps. It also scales flexibly with your growth.

Look for a Software-as-a-Service solution that provides both simplicity and depth. It should be intuitive enough for staff to quickly adopt while offering advanced configuration options. Automated sync, real-time visibility, and predictive analytics are key features of inventory management software.

Carefully evaluate solutions that fit your business model and requirements. Compare capabilities for order management, warehouse management, asset tracking, assembly production, and more. Read reviews and ask about integrations with your sales channels, accounting platform, and other systems.

Integration of AI and Machine Learning For Predictive Inventory Management

AI and machine learning capabilities are transforming inventory management. Software solutions can now analyze historical usage patterns and sales data to generate remarkably accurate demand forecasts.

This prevents inventory shortages and surpluses by considering internal and external factors impacting inventory needs over time. The technology self-learns and improves forecasting accuracy as more data is accumulated.

Intelligent reorder recommendations can prompt automatic restocking when retail inventory levels drop below target thresholds. This optimizes supply chain operations and cash flow.

Implementing Automated Reordering and Real-Time Inventory Tracking

Automating mundane inventory tasks is essential for scaling efficiently. Rules-based reorder systems can trigger purchase orders or manufacturing work orders when stock is depleted.

Real-time inventory tracking provides instant visibility down to the SKU level across multiple warehouses and sales channels. Barcode scanning, RFID, and IoT sensors enable effortless monitoring of receipts, put-aways, picks, and shipments.

These capabilities minimize perishability and theft while speeding up fulfillment. Customer service is improved by reducing backorders and stockouts.

With the right solutions and discipline, businesses can achieve new levels of inventory optimization. This leads to substantial cost savings, smarter cash flow management, and maximized sales revenue.

Measuring Success: KPIs

Key Performance Indicators (KPIs) enable quantitative tracking of inventory management effectiveness and operational efficiency. Common inventory-related KPIs that should be routinely monitored include days of supply, fill rates, cycle count accuracy, total supply chain costs, average cost, and inventory turns or velocity.

Days of supply metrics calculate the average number of days current inventory will last based on demand. This evaluates raw material, work-in-progress, and finished goods inventory levels against consumption rates. Fill rates assess the ability to fulfill orders from stock by dividing units shipped from inventory by units ordered. Cycle counting accuracy represents variance between physical counts and perpetual records to gauge systemic inventory errors. Total supply chain costs include expenditures like holding, shortage, ordering, acquisition, and fulfillment costs driven by inventory stocking approaches. Inventory turnover measures how many times the average inventory sells during a period. Higher velocities indicate leaner, more flexible inventory replacement cycles.

Together, these KPIs provide a holistic view, enabling data-driven adjustments of reorder points, safety stock levels, process flows, and inventory operations across the supply chain. By connecting vital metrics to frontline actions through visual dashboards and real-time analytics, managers can continuously improve inventory productivity over time.

Investing in Inventory Management Solutions

Inventory management has a major influence on business success across industries. Implementing efficient practices and smart technology solutions enables companies to align supply and demand, avoid stockouts, reduce carrying costs, and optimize overall inventory levels. With real-time visibility and predictive data analytics, businesses can achieve lean, accurate, and agile inventory control. This leads to better customer service through product availability and rapid order fulfillment. In a competitive landscape, effective inventory management delivers a strategic advantage to positively impact the bottom line. By making inventory a priority supported by innovative solutions, companies can transform it from an expense to a key driver of growth.