Augmented Operations: Enhancing Efficiency and Productivity

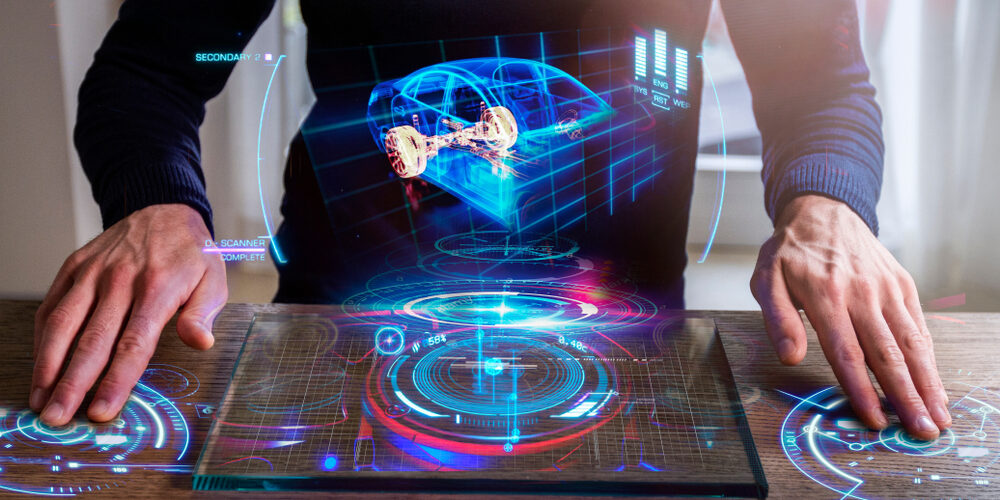

In today’s business landscape, staying ahead of the curve is no longer optional. It’s the difference between thriving and merely surviving. This is where augmented operations come into play – fueling efficiency, improving operations function, identifying measurable kpis, optimizing system design, and propelling productivity to unprecedented heights. By seamlessly infusing cutting-edge technology into their day-to-day processes, forward-thinking companies are not only revolutionizing their operations but skyrocketing their bottom line.

The Ultimate Guide to Augmented Operations

Introduction

A new revolution is taking place in the operations function, driven by advancements in technology like AI, Machine Learning, IoT, robotic automation, and other automation tools. These tech-savvy solutions facilitate various tasks, from predicting maintenance issues to guiding operations functions to alarms reduction to diminishing national security file errors.

Definition of Augmented Operations

Augmented operations are the application of automation tools, computer science, data structures, and other tech advancements to decrease the total resource cost test associated with operational tasks. Whether it’s alarms reduction or ticket number reduction, the goal is to make a business’ operations functions and operations staff more accurate, speedy, and cost-effective. In other words, the total resource cost test should pass with flying colors as the business strives to optimize those measurable kpis.

Importance and Benefits Of A Solid Augmented Operations Division

As the operational landscape continues to get more complicated, the need for automation tools that can deliver efficiency, along with augmented assignment operators to run them, has become paramount. This not only reduces human error but also boosts a business’ ability to analyze measurable kpis, simplify its operational manual, and enhance the performance of its operations staff.

Integration of Technology in Operations

Artificial Intelligence (AI)

AI and machine learning are the key drivers of an augmented operations division. They facilitate an in-depth analysis of complex data structures, assisting in resolution reduction and predictive maintenance.

Use of AI in Forecasting and Predictive Analytics

AI is widely used in the realm of predictive analytics. It visualizes patterns in a vast amount of data and predicts future problems which helps with future business planning built around measurable kpis.

Implementation of Machine Learning Algorithms in Process Optimization

These algorithms learn to adapt over time, leading to continuous improvement in performance and efficiency.

Internet of Things (IoT)

The IoT plays a significant role in augmented operations, with its ability to collect and analyze real-time data from a variety of sources.

Role of IoT in Collecting and Analyzing Data

The IoT devices collect real-time data and send it for analysis. This information aids in making better decisions and quickly responding to emerging issues.

Increasing Efficiency through Real-Time Monitoring and Automation Tools

With real-time monitoring of the IoT, operations can respond swiftly to situations, thus enhancing efficiency and resolution reduction. Furthermore, IoT automation helps reduce the manual workload on operations staff, thus improving overall operations function.

IoT Applications in Supply Chain Management and Maintenance

The IoT also finds its application in supply chain management. It aids in tracking goods in real time and ensures they reach their destination promptly. Additionally, it helps in the predictive maintenance of machines, further reducing the total resource cost test.

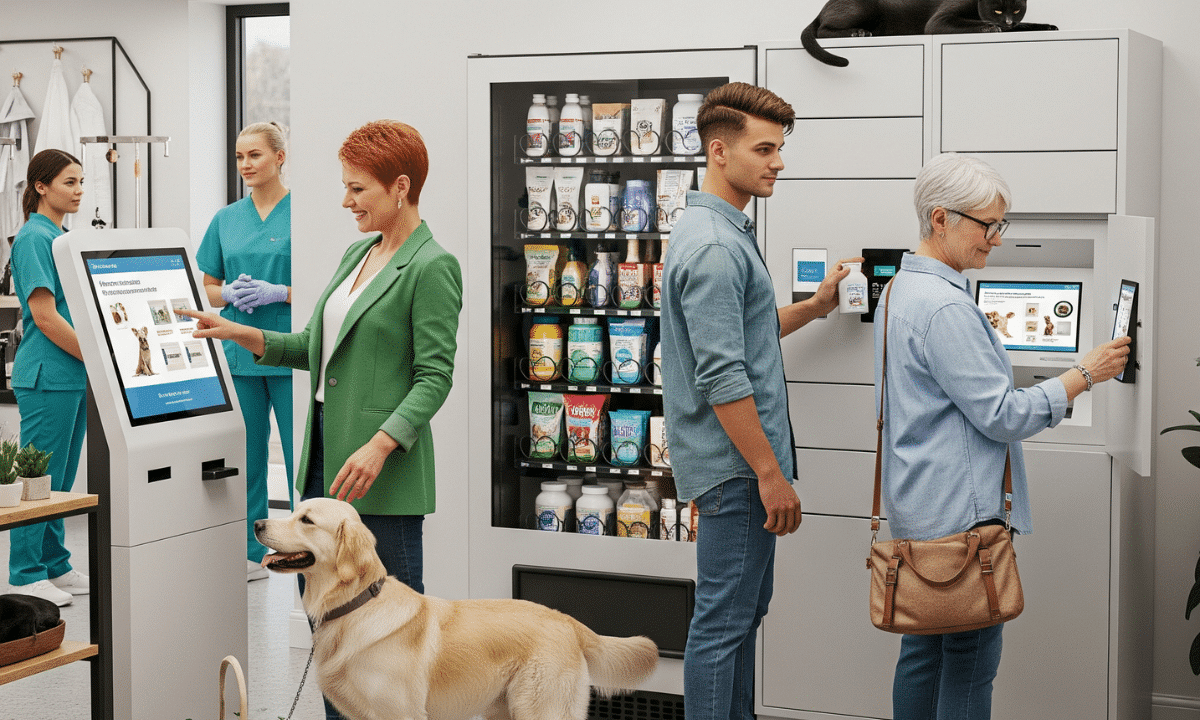

Robotics and Automation

Robotics and automation are usually employed for repetitive tasks where precision and speed are vital. The use of robots not only reduces human error but also decreases the operations staff workload.

Use of Robotics for Repetitive Tasks and Precision

Robots excel in carrying out repetitive tasks with high precision, which increases speed and ensures high accuracy and consistency, thereby optimizing a company’s measurable kpis.

Benefits of Automation in Improving Speed and Accuracy

The use of automation results in improved speed and precision, leading to better working conditions for operations staff and higher satisfaction for clients and end-users.

Predictive Maintenance: The Future of Augmented Operations

Experts predict that this is where the future lies – the process of predicting when a machine might breakdown or system design might fail and proactively scheduling maintenance to prevent that failure. This makes it possible to predict potential issues before they become problematic. Ultimately, an investment in this type of preemptive maintenance leads to measurable kpis, resolution reduction, and most importantly, alarms reduction.

Potential Future Developments

The future of augmented operations will further lean towards a proactive approach to maintenance, thus reducing total resource costs and optimizing operations staff. With the aid of machine learning algorithms, future technology will be capable of preempting potential hazards and ensuring optimal operations staff performance.