Streamlining Inventory: Best Inventory Management Practices

Managing inventory efficiently is vital for retailers, manufacturers, and distributors to maximize profitability and minimize waste. However, many companies still rely on manual processes and legacy systems that frequently lead to inaccuracies, stockouts, and bloated inventories.

By implementing automated tracking, perpetual inventory, optimized stock levels, and other best practices, businesses can streamline inventory operations for sustainable success and increased profits.

Leveraging Automated Tracking Systems

One of the most impactful ways to upgrade inventory management is by incorporating automated tracking systems. Manually counting stock and updating spreadsheets leaves too much room for human error. Automated tracking through barcodes, RFID tags, and inventory management software provides real-time visibility with minimal effort.

Barcoding Boosts Accuracy

Barcodes have long been used to speed up checkout and lookup of product information. Adding barcodes to individual inventory units through labeling or packaging provides other major benefits:

- Improved Inventory Accuracy: Barcode scans provide definitive input rather than estimation during counts.

- Faster Cycle Counting: Portable scanners enable counting portions of stock quickly.

- Item Tracking: Barcodes assigned to specific units or batches assist with recalls and loss prevention.

- Reduced Labor Costs: Less time is needed for inventory handling tasks like receiving and put-away.

Select barcodes that fit your inventory scale and workflow. Linear 1D barcodes are inexpensive and adequate for most items. 2D options like QR codes store more data to identify unique items. Make sure your POS system integrates with scanners to capture transactional data.

RFID Tags for Real-Time Visibility

Radiofrequency identification (RFID) tags represent the next evolution from barcodes. RFID uses electromagnetic fields to automatically identify and track tags attached to objects. Key advantages include:

- Hands-free Scanning: RFID readers can scan tags from up to 30 feet away without line-of-sight.

- No Manual Counts: RFID enables perpetual, automated inventory counts in real time. This is vital for every business, from large chains to small businesses, as it enables teams to save time.

- Enhanced Loss Prevention: RFID portals can detect tagged merchandise leaving stores.

- Improved Accuracy: RFID reduces errors by eliminating visual scans.

The upfront expense of widespread RFID adoption remains the main barrier. However, for high-value goods or complex supply chains, the long-term benefits outweigh the costs and make a significant impact on effective inventory management.

Inventory Management Systems

Sophisticated inventory management systems tie together critical sales, warehousing, and accounting data to optimize decision-making:

- Integrate with POS: Sync with sales transactions and update inventory records automatically.

- Generate Purchase Orders: Software can automatically create POs when the stock hits predefined thresholds.

- Optimize Picking and Put-away: Direct warehouse staff to locations based on real-time inventory.

- Provide Analytics: Gain insights into inventory metrics like turnover, shrinkage, and days on hand.

Look for user-friendly systems that won’t disrupt workflows. The benefits of automation and visibility outweigh the learning curves.

Perpetual Inventory for Constant Accuracy

Perpetual inventory represents the ideal approach for retailers today. Also known as continuous inventory, it means maintaining an ongoing, real-time record of inventory quantities rather than sporadic physical counts.

Combat Inaccuracy Issues

Traditional periodic inventory counts are plagued by discrepancies between actual and recorded stock levels. Causes include:

- Shrinkage: Shoplifting, damaged goods, administrative errors

- Poor Recordkeeping: Inaccurate POS, receiving or manual inputs

- Time Lags: Not capturing transactions in real-time

This results in inflated on-hand quantities on paper. Perpetual inventory mitigates this through automated tracking each time merchandise is moved.

Provide Constant Updates

Perpetual systems use technology like barcodes, RFID, and integrated software to immediately record inventory activity. Instead of shutting down to take stock, perpetual systems perform mini-counts throughout the day or week. This provides two key advantages:

- No work stoppages

- Frequent accuracy checks

Cycle counts can be randomized or focus on high-velocity products prone to shrinkage first. The goal is constant visibility, not scheduled assessments.

Balance with Physical Counts

Perpetual methods don’t make traditional physical inventory counts obsolete. Full manual counts should still occur periodically to verify and reset perpetual records. Think of perpetual systems as giving you an up-to-the-minute position, while full physical counts provide periodic baselines.

When used together, perpetual and periodic approaches provide comprehensive inventory accuracy and minimal business disruption.

Optimal Stock Levels Reduce Costs

Finding the ideal amount of inventory involves balancing the costs of excess stock against the risks of stockouts. Proper planning of reorder points and safety stock levels helps strike this balance.

Calculate Optimal Reorder Points

Inventory systems can automatically reorder stock when it hits predetermined levels. But first, you need to calculate optimal reorder points that account for variables like:

- Lead Time: How long to receive shipments from suppliers.

- Average Daily Unit Sales: The rate of sales depletion.

- Target Buffer: How much safety stock to keep on hand.

Add the lead time and buffer to the inventory level projected to last through average daily sales. This gives the reorder point that triggers replenishment before stocking out. Monitor sales velocity trends and supplier performance to update as needed.

Hold Adequate Safety Stock

Safety stock provides an inventory buffer in case demand exceeds forecasts or suppliers have delays. It’s an insurance policy against stockouts. Calculate safety stock levels based on:

- Average Lead Time: Longer shipments require more cushion.

- Demand Variability: Inconsistent sales necessitate more safety stock.

- Target Customer Service Level: Higher policies warrant more inventory.

Manage Excess Inventory

Holding too much inventory also leads to substantial costs, including:

- Storage fees

- Insurance

- Shrinkage

- The opportunity cost of capital

Set safety stock targets to provide an adequate – not excessive – cushion. Analyze historical demand variability and refine forecasting to steadily improve projections. This enables slimming down safety stock over time.

Par Levels Enable Lean Reordering

Closely related to optimal reorder points is setting par levels for inventory. Par levels represent the ideal quantity to have on hand at any given time.

Predetermined Stock Levels

Par levels are predetermined for each product based on criteria like:

- Average rate of sales

- Lead time to receive additional stock

- Minimum level to satisfy customer demand

For example, a retailer may set a par level of 20 units for a popular shampoo. Once the on-hand quantity hits 10, an automated reorder is triggered to refresh back up to 20.

Streamlined Replenishment

Maintaining par levels enables highly efficient inventory replenishment:

- No Constant Monitoring: Par levels trigger automatic reorders without human intervention.

- Minimal Risk of Stockouts: New stock arrives before reaching empty.

- No Order Calculation Required: Removes guesswork in determining reorder quantities.

- Leaner Overall Inventory: Par levels allow for tighter control of quantities on hand.

The initial par-level settings do involve forecasting and analysis. But the ongoing process is far simpler and nimbler.

Adapt to Trends

Par levels are not permanently fixed either. The predetermined quantities should be regularly reviewed based on sales patterns and external factors. For seasonal items, par levels can be programmed to automatically adjust over the year based on historic demand.

Like with optimal reorder points, par levels provide discipline and efficiency to the inventory replenishment routine.

Warehouse Layout Optimization

Sound inventory practices aren’t just about software settings and number-crunching. The physical warehouse layout and storage strategies also play a significant role in operational efficiency.

Logical Zoning

Classify warehouse zones based on activity, and locate inventory accordingly:

- Active picking zone for fastest movers – prioritize easy access to A products.

- Reserve storage for B and C items – place lower turnover items in secondary zones.

- Quality control area near receiving bays – enables quick inspection of incoming orders.

This allows picker travel time to align with item velocity patterns. Limiting exceptions reduces wasted motion and search time.

Signage and Labeling

Implement clear signage, floor markings, and product labels in picking zones to assist pickers. This minimizes confusion and errors for faster, more accurate order fulfillment.

Consider numbered aisles, shelf tags, fixed barcode locations, and painted floor lines designating zones. Like driving roads, navigation aid in warehouses helps prevent miscues.

Max Vertical Space Usage

Traditional layouts underutilize available cube space. Maximize vertical storage through:

- Floor-to-ceiling pick modules.

- Double-deep racking with walkways between.

- Mezzanines add extra storage levels.

This allows massive density and capacity within a fixed footprint. Leverage vertical space for expansion before adding warehouses.

Streamlined Receiving and Put-Away

Stage incoming inventory near receiving docks for quick inspection and processing. Directed put-away, facilitated by WMS technology, then places stock straight into optimal pick locations rather than interim holding, reducing touches.

This prevents backup of goods in and out of the warehouse. Staged receiving areas and directed storage to optimize inventory flows.

Warehouse Management Systems

Warehouse management systems (WMS) represent the central inventory technology solution for many omnichannel retailers today. Capabilities optimize nearly all aspects of warehouse operations:

Automated Data Collection

Instead of manual inputs, WMS automatically collects inventory data during receiving, put-away, and order fulfillment via mobile devices. This provides systemwide visibility and prevents human data entry errors.

Directed Fulfillment

Based on real-time inventory levels across zones, WMS directs pickers to the ideal items to fulfill orders. This minimizes travel distance and maximizes pick productivity.

Efficient Replenishment

By tracking on-hand inventory across zones in real-time, WMS can direct put-away to refill picking lanes before they are empty. This prevents “out of stock” picking scenarios that lead to travel waste.

Integrated Analytics

WMS contains robust reporting on metrics like perfect order rate, peak throughput, and cube utilization. This supports data-driven analysis to refine and improve operations.

As omnichannel complexity increases, WMS becomes an indispensable inventory optimization tool.

Omnichannel Inventory Visibility

Retailers operating brick-and-mortar stores, in addition to online channels, must integrate inventory management across all channels.

Unified Commerce Systems

Traditionally, in-store and web inventories were disconnected. Modern unified commerce systems consolidate all inventory data points into a “single source of truth” accessible across the enterprise.

Core Capabilities

- Shared Inventory Pool: All channels pull from the same stock.

- Cross-channel Order Fulfillment: Online orders can be fulfilled from stores and vice versa.

- Cloud-based Access: Browser-based means no software installs are required to check stock.

This provides true omnichannel inventory visibility and opens up fulfillment options to meet customer needs.

Store and Warehouse Transparency

When inventory quantities at brick-and-mortar stores are opaque, it frequently leads to online stockouts. Unified systems add store stock visibility to the web catalog.

Warehouse and distribution center inventory also becomes visible across channels. This enables seamless drop-shipping direct to customers regardless of original stocking location.

Accurate Order Promising

Omnichannel visibility allows retailers to clearly see the collective quantity available across channels to accurately promise orders and delivery times. This prevents overselling inventory.

The future of retail requires breaking down channel silos. Shared inventory data and fulfillment capabilities keep omnichannel operations running smoothly.

Employee Training for Inventory Discipline

With all the focus on inventory technology and analytics, the human element cannot be ignored. None of these systems operate themselves. Proper training and accountability for staff handling inventory remains crucial for minimizing shrinkage.

Standardized Processes

Create detailed standard operating procedures for inventory processes. These should provide clear, step-by-step instructions for activities like receiving, counting, picking, and reconciling variances.

Enforce the use of these SOPs through training and evaluation. This promotes discipline and consistency.

System Usage

Require staff to use enterprise inventory systems like barcoding and WMS to execute all inventory transactions. Avoid off-system records or manual workarounds that lead to inaccuracy.

Incentivize proficient system usage through performance metrics and rewards programs. This drives adoption.

Security Protocols

Install security controls like cameras, tags, and exit checkpoints. But also train staff on alerting protocols for shrinkage risks like damaged packaging or unaccounted inventory movements.

Create a transparent, non-punitive process for reporting suspicious activity, errors, and system bugs. Employees who feel safe surfacing inventory problems enable early risk detection.

Technology lays the foundation, but nothing replaces well-trained, ethical employees vigilantly following protocols to keep inventory records clean across the enterprise.

Prioritizing Inventory Management

Inventory accuracy and efficiency separate the high-performing retailers from the rest. While we often think of inventory strictly in terms of numbers, dollars, and units, it is ultimately about satisfying customer demand. Having the right products in the right quantities at the right locations is foundational to keeping shoppers happy and loyal.

The practices covered in this guide – leveraging perpetual systems, optimizing stock levels, storage and replenishment approaches, omnichannel visibility, and others – enable retailers to sustainably achieve inventory excellence. Falling short in these areas not only hurts service levels but also leads to major profitability drains through shrinkage and excess.

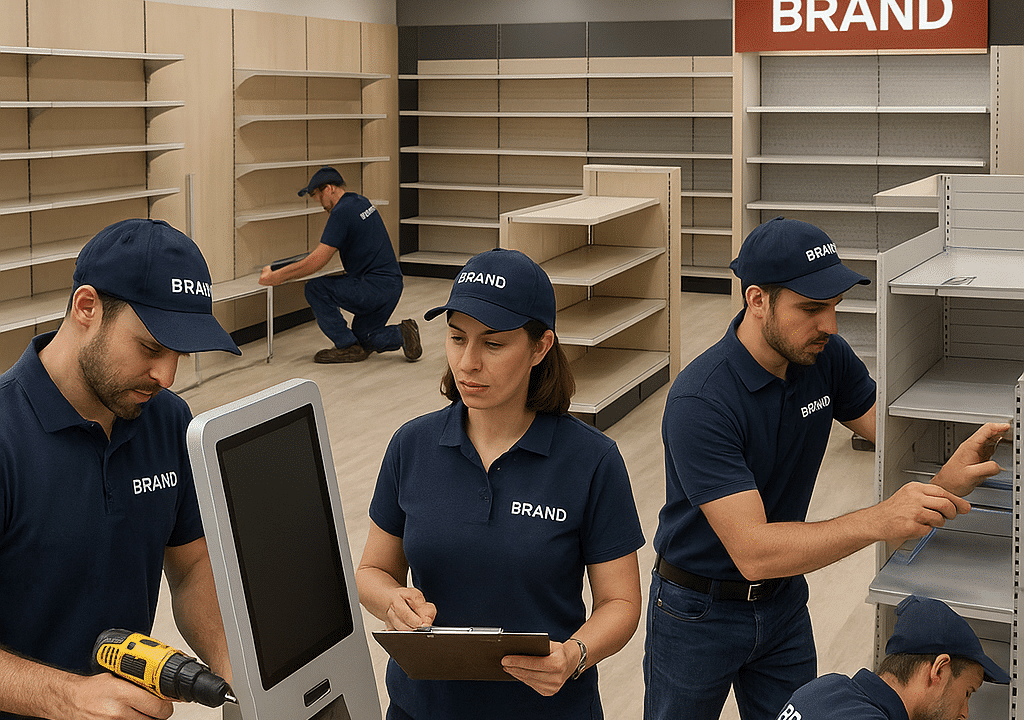

Look to T-ROC Global for Inventory Management Assistance

At T-ROC Global, we combine the power of people and technology to create solutions for brands, retailers, and manufacturers. We have extensive experience and expertise working with retailers to develop inventory management practices that help them track, organize, and manage sales. Our real-time management systems rely on RFID technology to provide unparalleled data and insight.

When you work with us, we handle every aspect of the process, from selecting hardware and software to tagging each and every item. We even train teams on how to accurately scan for inventory counts.